|

Neware Techonology ltd.

|

Neware battery charge and discharge testing system

| Payment Terms: | T/T,WU |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

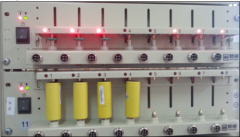

8 channel Computerized electrochemical test equipment can be to do battery DCIR, Pulse Test, HPPC, Rate, Static capacity, cycle life and etc.

Neware battery charge and discharge testing system

This tester BTS-10v6a is a rang of high precision battery testing system, which designed primarily for Li-polymer, Li-ion, Ni-Ca, Lead acid etc. batteries combine capability tests.

Neware battery charg and discharge testing system according to the international standard design, each channel of the system has an independent constant-current source and a hardware constant-voltage source. Constant-current source and constant-voltage source can be programmed and controlled as desired. In addition, an independent pulse source is added to each battery channel to meet with the requirements of dynamic internal resistance measurement.

Neware Battery Testing System series adopts module construction. With plug-and-play design, the user can freely remove and load the module units under a nonstop status without interrupting other module units' normal running. This function is convenient for the system's maintenance.

Performance

Each module provides 8 independent programmable channels

With built-in power supply, and complete controllable circuit, each module can work independently. Each channel can set different working modes. Channels are completely independent.

Fine programming characteristic

The system software can set working steps and working parameters, working modes of each step flexibly. Working modes includes constant current discharge, constant current charge, constant voltage charge, rest, GOTO, (internal resistance measurement). Each working modes can set voltage, current, time, capability, negative voltage slope, and other limit conditions, the relation of which is "logic or". When the present limit conditions are met, the system will continue next working mode automatically. The set program can be saved and opened in the form of Schedule.

Complete controllability

The system software has GOTO, restart and resume functions which allow the user to change the working parameters at any time.

Windows-based software interface, Stable performance, and easy operation

The operation mode of the system' software is close to that of its excellent foreign counterparts and is easy to operate. With real-time monitoring windows and integrated graph/data windows, the testing process can be observed more directly and efficiently. During the test, the software will give timely instructions and warnings, provide intelligent help.

Powerful data and graph processing function

The software of The Neware Battery Testing System adopts standard SQL data-base management, and is compatible with Access, Excel. It features large data processing capacity. The user can define the curve coordinate himself such as voltage-time curve, current-time curve, capacity-voltage curve, loop times-charge/discharge capacity curve, loop times-charge/ discharge efficiency curve, etc.

Dynamic battery internal resistance test (optional)

Each channel of The Neware Battery Testing System has a built-in pulse source which can calculate battery's internal resistance by means of applying HF pulse to the battery and measuring the battery's sub-voltage. Internal resistance test can be conducted automatically during the process of charge and discharge.

Advanced and easy-to-use battery grading function

According to the battery's capacity, internal resistance and charge/discharge platform, the Neware Battery Testing System series can grade the batteries. After the user set the standards of separation, the system will analyze the test result data automatically, confirm the consistency indicators for the batteries under test and provide a test result report. At the same time, the LED on the channel will indicate the physical location of the batteries with the same grade.

Complete test process record (log function)

The Neware Battery Testing System series can make a complete record of all the events happened in the test. During the process of test, some accidental events such as power failure, system shut down, erroneous communication, erroneous operation and forced operation and so on will lead to sudden changes of the test data (sudden changes of the voltage or current). By checking the record, user can more easily find these external interferential causes.

Intelligent power failure protection

In the event of power failure in the process of test, the testing system will automatically shutdown preset running channels. And when the power failure has recovered, the system will automatically resume those stopped channels and ensure that the test is normally conducted and the date will never lose at any cases.

Specially made battery clips

The Neware Battery Testing System series provides many types of battery clips. The relative separation of the clips and the machine as well as the software and hardware self-protection of the system (over voltage, over current, etc) increase the safety of the system greatly and ensure the user's carefree test.

General-purpose (4 leads) clips: This type is designed under the proposal of the experts and to meet the requirement of mass production. It is applicable to fix various types of cylinder and square batteries. This type is reliable, durable and easy to maintain.

Clips for R&D use: This type can lead out all the charge/discharge electrodes and measuring electrodes by using alligator clips and facilitate the fixing of any type of abnormal-shaped batteries or battery groups.

Li-polymer battery clips, with a constant temperature cabinet.

4-electrode measuring

All the battery fixtures have 4 electrodes, including 2 current ends and 2 voltage measuring ends. Multi-electrode measurement improves measuring accuracy.

Battery charge and discharge testing system technical information:

| BTS-10V6A | Battery Testing System | |||||||||||||||

| Model: | BTS- | 10 | V | 6 | A | Material Code: | CT-4008 | -10V6A | - | NTA | - | P | ||||

| Description | Product Specification | |||||||||||||||

| AC Input | AC 220V ±10% / 50Hz | |||||||||||||||

| Power | 768 | W | ||||||||||||||

| Resolution | AD: 16bit; DA: 16bit | |||||||||||||||

| Impedence Input | ≥1MΩ | |||||||||||||||

| Voltage | Measuring Range | Charge: 50mV~10V | Dischrge: 50mV~10V | |||||||||||||

| Discharge Min Voltage | 2.5V | |||||||||||||||

| Accuracy | ± 0.1% of FS | |||||||||||||||

| Stability | ± 0.1% of FS | |||||||||||||||

| Current | Range | Charge: 30mA~6A Discharge: 30mA~6A | ||||||||||||||

| Accuracy | ± 0.1% of FS | |||||||||||||||

| Stability | ± 0.1% of FS | |||||||||||||||

| Power | Output Power Per Channel | 60W | ||||||||||||||

| Stability | ±0.2% of FS | |||||||||||||||

| Time | Rise Time | 20ms (10%FS~90%FS) | ||||||||||||||

| Step Time | ≤ (365*24) hours/step | Time Format 00:00:00:000 ( h:min:s:ms ) | ||||||||||||||

| Aux Channel | Aux Input | Temperature | ||||||||||||||

| Temperature | ﹣25℃~110℃ | |||||||||||||||

| Temperature Accuracy | ±2℃ | |||||||||||||||

| Temperature Resolution | 0.1℃ | |||||||||||||||

| Voltage Range | ||||||||||||||||

| Voltage Accuracy | ||||||||||||||||

| Data Accquisition | Intervals | Time Interval Δt: (100ms~60000s) | ||||||||||||||

| Voltage Interval ΔU: (20mV~10V) | ||||||||||||||||

| Current Interval ΔI: (12mA~6A) | ||||||||||||||||

| Frequency | 10Hz | |||||||||||||||

| Charge | Modes of Operation | CCC, CVC, CC & CVC, CPC | ||||||||||||||

| End Conditions | Main Channel: Voltage, Current, Test Time, Capacity | |||||||||||||||

| Aux: Temperature | ||||||||||||||||

| Discharge | Modes of Operation | CCD, CPD, CRD | ||||||||||||||

| End Conditions | Main Channel: Voltage, Current, Test Time, Capacity | |||||||||||||||

| Aux Channel: Temperature | ||||||||||||||||

| Pulse | Charge | CCC | ||||||||||||||

| Discharge | CCD | |||||||||||||||

| Minimum Pulse Width | 500ms | |||||||||||||||

| Automated Switch | Automated switch from charge to discharge for each pulse | |||||||||||||||

| End Condition | Voltage, Test Time | |||||||||||||||

| Cycle | Cycles | Max 65535 | ||||||||||||||

| Steps | 254 | |||||||||||||||

| Nested Fuction | Max three levels of loops | |||||||||||||||

| Protective Function | Software | ● Power-off data protection | ||||||||||||||

| ● Off-line Operating | ||||||||||||||||

| ● Main Channels: user-defined safety(upper and lower)tolerance of current, voltage and delay time | ||||||||||||||||

| ●Aux Channels: User-defined safety (upper and lower) tolerance of temperature | ||||||||||||||||

| Hardware | Reverse-connecting protection | |||||||||||||||

| Channel Features | Independent pairs of closed loops for constant current source and constant voltage source | |||||||||||||||

| Channels | Independent Control | |||||||||||||||

| Detection and Sampling | 4-wire Connecting | |||||||||||||||

| Noise Density | <85dB | |||||||||||||||

| Data Management | MYSQL Database | |||||||||||||||

| Communication Means | TCP/IP Protocol | |||||||||||||||

| Export Formats | EXCEL2003,2010,TXT,Graph | |||||||||||||||

| Communication Interface | Ethernet Port | |||||||||||||||

| Number of Channels Per Cabinet | 8 | |||||||||||||||

| Assignable Aux Temperature Per Channel | Max 248 | |||||||||||||||

| Operating Environment | ||||||||||||||||

| Description | Product Specification | |||||||||||||||

| Operating Temperature | 0℃~40℃ | |||||||||||||||

| Storage Temperature | -10℃~50℃ | |||||||||||||||

| Operating Humidity | ≤70% RH | |||||||||||||||

| Storage Humidity | ≤80% RH | |||||||||||||||

| Description | Product Specification | |||||||||||||||

| Battery Holder | Universal Holder | |||||||||||||||

| Holder Picture | ||||||||||||||||

| Universal Holder | Alligator Holder | Polymer Holder | Wiring Terminal | |||||||||||||

| Picture for reference, please confirm the actual product | ||||||||||||||||

Our advantages:

All kinds of types are manufactured for a range of current from 1mA to 1000A, a range of voltage from 5V to 500V to meet customers' special needs. We also provide the BTS which can test the voltage of 0 V or even lower.

1.Reasonable Price, standarbale and Reliable Product.

2.Improve the quality and life expectancy of your products

3.Work Performance more effective and efficacy

4.17years innovation guarantees you a in better future.

Warranty and Customer Service:

Neware warrants its equipment for 1 year from shipment, to be free from defects in workmanship and material. For some other consumptive materials, like battery clamps, we provide a 3-month warranty. This warranty, including customer service support and software licenses, is not transferable. Meanwhile, we provide lifetime software update

service to help your equipment optimized in its best status.

We provide below customer services:

1.Free Technical Training.

2.Free Service Call Service.

3.Testing Service.

4.Calibration Service.