|

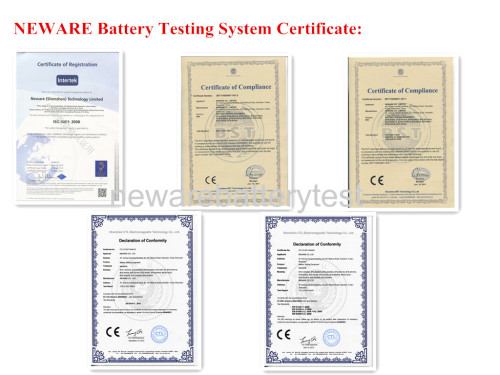

Neware Techonology ltd.

|

Battery Test Equipment for Battery Research

| Price: | 1.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Battery Testing System, Battery Testing Equipment, Coin cell, punch Cell, battery test, materials research, energy storage

Neware Battery Testing System series is a general purpose, multi-channel battery testing system for Li-polymer, Li-ion, Ni-MH, Ni-Cd, etc, batteries. This system provides most applications in battery testing fields such as materials research, battery performance test, small-scale battery formation, capability grading, battery pack testing, etc.

According to the international standard design, each channel of the system has an independent constant-current source and a hardware constant-voltage source. Constant-current source and constant-voltage source can be programmed and controlled as desired. In addition, an independent pulse source is added to each battery channel to meet with the requirements of dynamic internal resistance measurement.

Neware Battery Testing System series adopts module construction. With plug-and-play design, the user can freely remove and load the module units under a nonstop status without interrupting other module units' normal running. This function is convenient for the system's maintenance.

Battery testing equipment series

1.Low Power Series (5V1mA-5v500mA):For Button batteries, coin cells and other test.

5V1mA, 5V5mA, 5V10mA, 5V20mA, 5V50mA, 5V100mA, 5V200mA,5V500mA.

2.Mobile phone battery cell series

5V3A, 5V6A,

3.Mobile Power Testing System series

6V4A,10V3A,10V6A,20V6A

4. SMBus

20V6A. 15V3A,

5. E-bike,E-Moto pack,Tool power and other pack

5V10A,5V20A,5V30A 5V40A,5V50A,5V60A,5V100A, 5V200A,5V300A,

5V500A,5V1000A 10V60A,15V40A,20V40A;36V10A, 10V6A,20V3A

60V20A, 60V60A, 60V40A, 60A100A, 60V200A, 110V100A

6. Car battery,Energy storage battery,UPS battery,EV/HEV/PHEV high power battery

70V300A, 110V180A,800V1000A, 800V600A, 750V300A,700V100A,

600V700A, 600V500A, 500V300A, 500V100A

7. For battery alive and Sub-capacity

5V3A,5V20A

8. BVIR series Resistance test

9. BTS-9000 High performance testing system(4 ranges.Accuracy 0.02%)

10.The battery testing system can be customized according to your request as 1mA-1000A,5V-800V

BTS-3000 standard power battery tester

BTS3000 is based on Neware 3rd generation testing system,in 2006,the 1st high power equipment BTS-3000-5V1000A,BTS-3000-60V300A were developed successfully and introduced to both domestic market and oversea market. their high-performance has been qualified by the market through out the years. It is reliable and time-tested for battery capacity grading and performance testing solutions.

BTS3000 mainly used for power batteries' grading and formation,capacity testing and cycle life testing.

BTS3000 is now the most popular type in the battery testing field, and it serves for research institutes, universities and battery manufacturers all around the world.

Specification

System Features

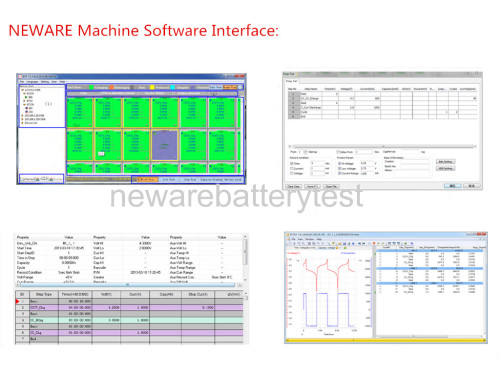

1.Adopt industrial grade 32-bit embedded platform,step files could be downloaded to device to execute;

2.Hardware adopt independent constant current source,constant voltage source;

3.Each channel could be controlled independently;

4.Each step document support up to 254 steps;

5.Each step document could program 65535 cycles and nest 3 layers;

6.Support single step recording conditions and the protection conditions;

7.Hardware against reverse protection, voltage,current,capacity anomaly protection;

8.Support offline testing,the data storage space of equipment up to 1GB;

9.Based on TCP/IP protocol; Support LAN remoter monitoring;

10.Adopt database, manage testing data intensively,powerful data retrieval and traceability function;

11.Support curve comparison,flexible and customized automatic reports,support excel txt.

BTS 4000 high power battery tester

BTS4000 is based on Neware 4th-generation testing system, and was introduced into the market in 2008. BTS4000 applies plus EV battery pulse test, DCIR (direct current internal resistance) test.Cycle Life test and high rate charge /discharge test.

BTS4000 is now widely used by research institutes, university and EV battery manufacturers.

Specification

System Features

1.Adopt industrial grade 32-bit embedded platform,step files could be downloaded to device to execute;

2.The data recording frequency be up to 10Hz;

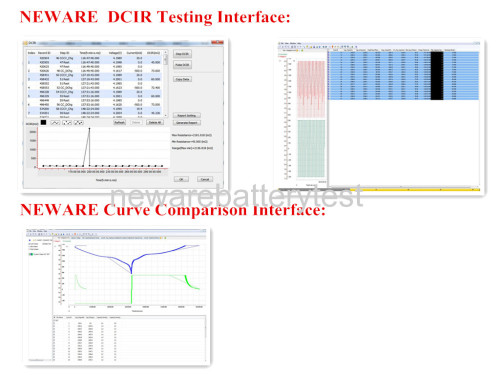

3.Support DCIR(DC internal resistance) test,the test result can be calculated automatically;

4.support pulse charge and discharge function,the time control accuracy of pulse test is ≤1ms;

5.Each pulse step support 32 different pulse segments;

6.Each channel could be controlled independently.Each step document support up to 254 steps;

7.support "if" step,can "go to" any step according to end condition;

8.Each step document could program 65535 cycles and nest 3 layers;

9.Support single step recording conditions and the protection conditions;

10.Support Conditional Recording;

11.Support Hardware against reverse protection, voltage,current,capacity anomaly protection;

12.The switch time of charging to discharging less than 10ms(pulse model);

13.Support offline testing,the data storage space of equipment up to 1GB;

14.Based on TCP/IP protocol; Support LAN remoter monitoring;

15.Adopt database that can manage testing data intensively,have powerful data retrieval and traceability function;

16.Support curve comparison,flexible and customized automatic reports;support export testing data in Excel,TXT format;

BTS 8000 Driving Cycle Simulation

Battery performance and cycle life are the two focuses of all kind battery tests.

It normally uses constant current or constant power and simple cycles for those 3C(Computer, Communication and Consumer Electronics)batteries.For EV(Electric Vehicle) energy systems, there are many variables to get into considerations.These tests are demanding and require much higher physical and electrical performance than a constant-current cycling regime.Tests commonly used today are FTP-75(EPA Federal Test Procedure), NEDC(New European Driving Cycle)and the newly WLTP(Worldwide harmonized Light vehicles Test Procedures).

These tests have shown to be a much better prediction of battery performance or life cycle than is constant-current or constant-power cycling.

BTS 9000 Battery Material Research

BTS 9000, as our latest testing architecture, brings you newly updated and sophisticated hardware technology, and brand-new software experiences – an experience that allows you operate our software as easy as operating Windows. It is characterized with a maximum data acquisition frequency of 1000Hz, multi current ranges, and a typical accuracy of 0.02% FS. BTS 9000 allows you perform pulse tests with a minimum pulse width of 400us.

EVT 6000

Characterized with IGBT, reversible AC/DC converter and CAN supported, our BTS 7000 brings you higher energy efficiency, smaller space and much convenient to utilize the existing gauge integrated in BMS/BMU.

IGBT 7000

Characterized with IGBT, reversible AC/DC converter and CAN supported, our BTS 7000 brings you higher energy efficiency, smaller space and much convenient to utilize the existing gauge integrated in BMS/BMU.

Our auxiliary single voltage sensors will help you capture the voltages of every single cell in series. this will largely increase the testing safety. You can have an advanced control based on the captured values.

Our advantages:

All kinds of types are manufactured for a range of current from 1mA to 1000A, a range of voltage from 5V to 500V to meet customers' special needs. We also provide the BTS which can test the voltage of 0 V or even lower.

1.Reasonable Price, standarbale and Reliable Product.

2.Improve the quality and life expectancy of your products

3.Work Performance more effective and efficacy

4.18years innovation guarantees you a in better future.

Warranty and Customer Service:

Neware warrants its equipment for 1 year from shipment, to be free from defects in workmanship and material. For some other consumptive materials, like battery clamps, we provide a 3-month warranty. This warranty, including customer service support and software licenses, is not transferable. Meanwhile, we provide lifetime software update

service to help your equipment optimized in its best status.

We provide below customer services:

1.Free Technical Training.

2.Free Service Call Service.

3.Testing Service.

4.Calibration Service.

Payment&Shipment

Delivery Detail: Negotiation

Payment: T/T or Western Union in advance or 30% deposit,balance before shipment.

Shipment:

Shipment way: DHL, UPS, FedEx, EMS,etc. Once we ship the goods, we will provid you the DHL/UPS tracking number next day.

Shipping Charges: Shipping rates quoted are estimates only. Shipping charges are calculated by our courier's automated system.

Shipping Delays: We do everything we can to meet the delivery time specified for each product, however occasionally delivery times may be affected by factors beyond our control and cannot be guaranteed. We will inform you if we become aware of an unexpected delay.